6A10 cobot, the foundry revolution

Grinding is a tedious task that all professionals seek to mechanize, or even automate. But is it always possible?

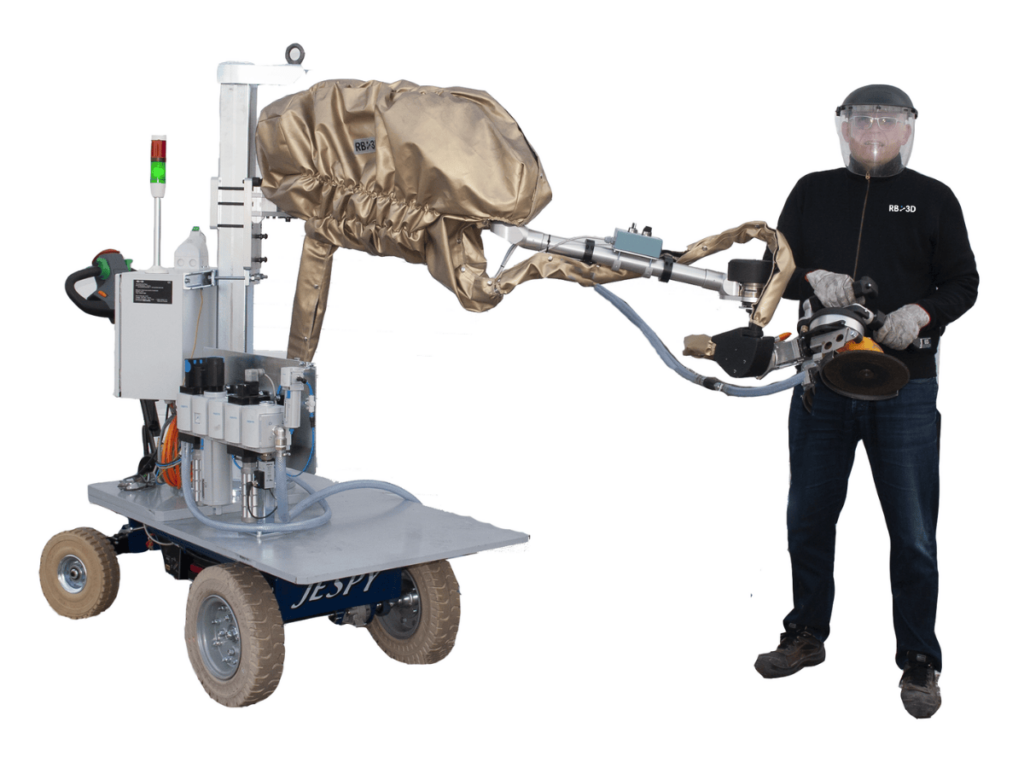

At RB3D, we know that it is not because some parts require a powerful, practical and secure tool. It is with this in mind that our 6A10 cobot, grinding assistant, was designed.

Cobot 4A350, your quality ally

Manual handling is responsible for many MSDs in companies and also impacts product quality. Find out how to fix it!

Assistant 6A10: When grinding rhymes with efficiency!

The 6A10 cobot stands out from other tools on the market due to its effectiveness on large, flat parts made of very hard materials. Why?

Cobot 4A350, handle your loads simply and effortlessly

Discover the benefits of the RB3D load manipulator: the 4A350 cobot. The most efficient effortless handling system on the market!

6A10 Grinder Assistant, a turnkey solution

Emmanuel tells us about the evolution of the 6A10 cobot over the years… A model now approved by the metallurgy industry.

4A350, handling loads has never been easier

Various manipulator technologies exist to meet the need for handling heavy loads, but not all of them allow for efficient work.

6A10, optimized grinding

As we saw previously, 6A10 grinding cobot has a very advanced control system. However, so much technology is only useful if it provides undeniable ergonomic benefits to the user.

4A350, what’s guidance assistance?

When using the 4A350 manipulator, the operator has guidance assistance. The objective is to allow him not to ask any questions during sensitive handling operations.

6A10, grind with complete control!

The controls of 6A10, grinding assistant cobot, allow the operator to work safely, fluidly and effortlessly.

4A350, take control

The 4A350 load manipulator is controlled simply and intuitively thanks to its intention bar. This is mounted on force sensors, allowing the cobot to transcribe the user’s intention while moving.