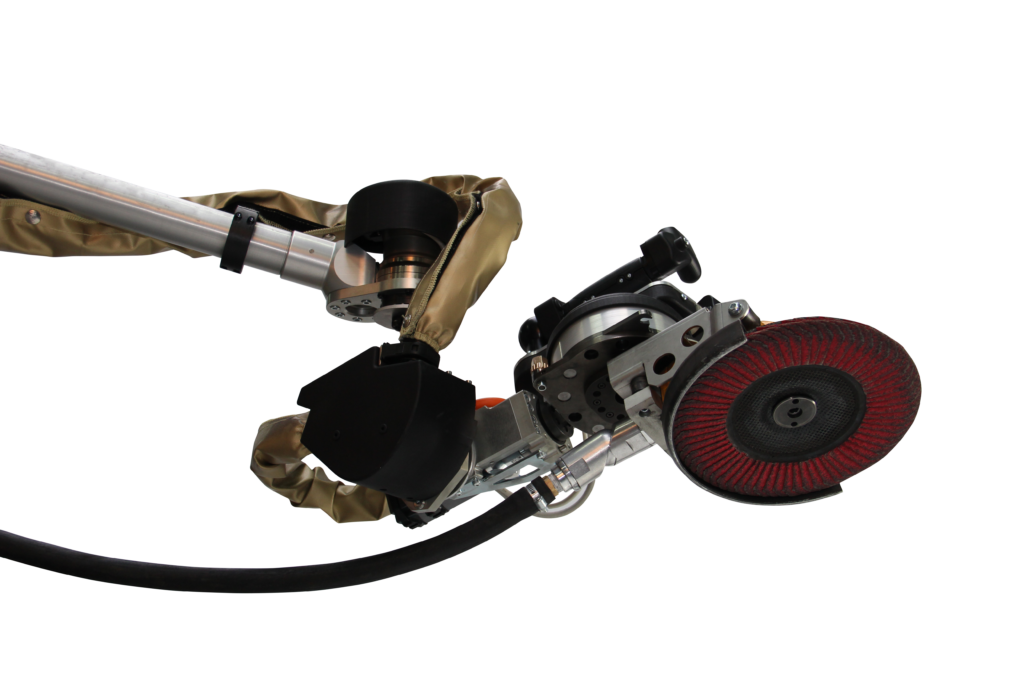

6A10, optimized grinding

As we saw previously, 6A10 grinding cobot has a very advanced control system. However, so much technology is only useful if it provides undeniable ergonomic benefits to the user.

4A350, what’s guidance assistance?

When using the 4A350 manipulator, the operator has guidance assistance. The objective is to allow him not to ask any questions during sensitive handling operations.

6A10, grind with complete control!

The controls of 6A10, grinding assistant cobot, allow the operator to work safely, fluidly and effortlessly.

4A350, take control

The 4A350 load manipulator is controlled simply and intuitively thanks to its intention bar. This is mounted on force sensors, allowing the cobot to transcribe the user’s intention while moving.

6A10, focus on orders

The 6A10 cobot is controlled by its end, what RB3D calls the intention rudder. This control surface is made up of 2 types of sensors

Success for the 4A350 in the food industry!

Last August, our team was proud to announce that the 4A350 was positively evolving towards new applications, notably the handling of reels of cling film 🤗

6A10, the force is with you

Abrasive manufacturers will tell you that to be effective in grinding you must ensure a significant contact pressure between the grinding disc and the area to be shaved.

4A350, load manipulator cobot

Manual handling of loads is one of the leading causes of work accidents recorded by Social Security.

6A10, your ally against vibrations

The 6A10 cobot was designed with the aim of solving the problems linked to grinding operations in metallurgy, by reducing the arduousness and risks for operators.

4A350, new application in the food industry

In 2022, our 4A350 cobot for the charging port was called upon to meet a new need.A cling film manufacturing company was looking for a solution to relieve its operators when handling reels.